When you look at an SMD LED screen, you see vibrant colors and sharp images. What you don’t see is the tiny chip packaging technology behind it. The choice between COB (Chip on Board) and SMD (Surface-Mounted Device) packaging has a direct impact on how a display performs over time. Understanding this difference helps buyers and project managers choose the right LED solution for their needs.

What Is an SMD LED Screen?

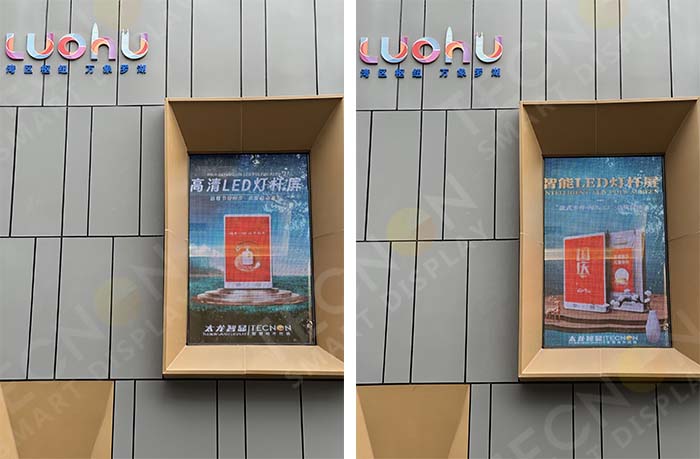

An SMD LED screen uses chips that are mounted directly onto the surface of a printed circuit board. Each LED combines red, green, and blue diodes in a single package, which produces rich color and wide viewing angles. This design makes SMD displays popular for both indoor and outdoor use, from stadium scoreboards to corporate video walls.

How COB Packaging Differs

COB technology packages multiple LED chips directly onto the substrate without individual housings. This method reduces gaps between diodes and improves durability. It also delivers better resistance to dust, moisture, and impact, which makes it appealing for high-traffic public spaces and demanding outdoor environments.

Key Performance Factors

Brightness and Color Consistency

An SMD LED screen typically offers excellent brightness and color uniformity, making it ideal for applications that require lifelike visuals. COB panels, however, provide deeper black levels and reduced glare due to their seamless surface design. For indoor museums or control rooms, COB might outperform in fine detail.

Durability and Maintenance

Over time, dust, scratches, and heat can affect LED panels. SMD modules are easier to replace individually, but they are more vulnerable to physical damage since the diodes are exposed. COB packaging seals the chips under a protective resin layer, increasing shock resistance and reducing the risk of diode failure.

Heat Dissipation

Both COB and SMD generate heat, but their handling differs. SMD LED screens use standard PCB designs with cooling systems, while COB technology has a more compact structure that allows for efficient thermal management. Stable heat control extends the life of the display.

Viewing Experience

For large outdoor billboards, the SMD LED screen remains dominant because of its high brightness and proven performance. For small-pitch indoor installations, such as conference rooms or command centers, COB’s tighter pixel alignment often delivers smoother visuals without visible gaps.

Cost and Scalability

Price is another key factor. SMD LED screens are more affordable, especially for large-scale projects, since the technology is mature and mass-produced. COB solutions usually cost more upfront but may save on maintenance and replacement costs in the long run.

Choosing the Right Technology

The decision between COB and SMD is not about one being better than the other. It depends on the application:

- Choose an SMD LED screen for large outdoor displays, versatile indoor walls, and projects where cost-efficiency matters.

- Choose COB LED panels for fine-pitch, high-traffic, or premium installations where durability and seamless visuals are priorities.

Conclusion: Long-Term Performance Matters

Both COB and SMD packaging affect how an screen performs over time. An SMD LED screen remains a reliable, versatile choice for most projects, while COB technology is gaining ground in high-end indoor applications. By understanding these differences, decision-makers can invest in a display that not only looks good on day one but also stands the test of time.

Tecnon Smart Display Technology Shenzhen Co., Ltd.

Tecnon Smart Display Technology Shenzhen Co., Ltd.