When an LED screen reaches the end of its service life, the real work is not over. Too many old displays still end up in landfills, even though most of their parts can be reused or recycled. A forward-looking LED screen supplier should think beyond manufacturing and installation. They should also plan how to recover, dismantle, and repurpose equipment. This reduces waste, saves resources, and creates long-term trust with customers.

Why LED Screen Decommissioning Matters

Every LED display—whether a digital billboard, a rental stage wall, or an indoor video screen—has a limited lifespan. Heat, humidity, UV exposure, and heavy operation eventually cause dead pixels, color drift, or power supply failures. Without a decommissioning plan, cabinets, modules, and electronics often end up as hazardous waste.

By offering sustainable end-of-life solutions, a professional LED display supplier protects the environment and strengthens customer relationships. Businesses and governments increasingly prefer suppliers who can handle the full lifecycle of their screens, not just the sale.

The Role of an LED Screen Supplier in Zero-Waste Management

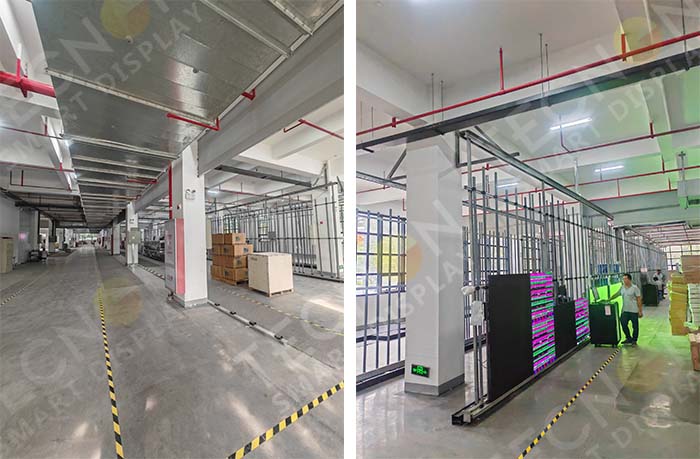

A responsible manufacturer can design products with decommissioning in mind. Modular cabinet structures, standardized connectors, and replaceable LED panels make dismantling easier. When products are built this way, it becomes simple to separate aluminum frames, steel sheets, power units, and control cards.

Some suppliers already offer buy-back or trade-in programs. These programs allow clients to return old equipment in exchange for discounts on new screens. Instead of disposal, parts are tested, repaired, and resold for secondary applications. This practice keeps valuable materials in circulation and avoids unnecessary landfill waste.

Step-by-Step: Breaking Down an LED Screen for Reuse

The zero-waste roadmap for decommissioning follows a clear process:

- Cabinets and frames: Most are aluminum or steel. These metals are highly recyclable and can be melted for reuse in other industries.

- Power supplies: If they still function, they can serve as spare parts for ongoing projects. Faulty units can be dismantled to recover copper and other valuable metals.

- LED modules: While not all modules survive, many can be repaired or repurposed for smaller installations. A worn outdoor P6 screen, for example, can be reconfigured for indoor use at lower brightness.

- Control systems: Processors, sending cards, and cables are often reusable if compatible with current standards.

With proper planning, an outdoor LED screen supplier can reduce waste by more than half compared to traditional disposal.

Challenges and Supplier Solutions

Recycling is not always straightforward. Adhesives, coatings, and certain semiconductors are difficult to process. This is where suppliers need strong partnerships with certified e-waste recyclers. Some advanced programs extract rare elements like gallium and indium from LED chips. Others experiment with biodegradable materials for casings or low-toxicity solder for easier recovery.

Another challenge lies in logistics. Collecting and transporting large LED cabinets requires specialized teams. Suppliers can build reverse logistics systems, either independently or in cooperation with municipal recycling programs. This service not only reduces waste but also reassures clients that decommissioning is handled professionally.

Business Value in Zero-Waste Decommissioning

Sustainability is no longer just a trend; it is a business advantage. A commercial LED screen manufacturer who offers decommissioning services gains several benefits:

- Customer loyalty: Clients prefer working with suppliers who manage the full lifecycle of a product.

- New revenue streams: Trade-in and refurbishment programs create recurring business opportunities.

- Stronger bids: Many government projects require sustainability commitments. Suppliers with zero-waste programs are more competitive in tenders.

- Brand reputation: Eco-conscious practices set a supplier apart in a crowded market.

In short, decommissioning done well is not a cost—it is a growth strategy.

The Future of Sustainable LED Displays

The market is moving toward circular design. Tomorrow’s LED video wall supplier will focus on eco-friendly materials, modular parts, and long-term repairability. Buyers already ask tough questions about carbon footprints, disposal plans, and recycling options. Suppliers who adapt early will lead the industry and set higher standards.

By treating decommissioning as a core responsibility, not an afterthought, the modern LED screen supplier can deliver real value. A zero-waste roadmap benefits the planet, customers, and the supplier’s own business. This is how the industry builds trust and prepares for a sustainable future.

Tecnon Smart Display Technology Shenzhen Co., Ltd.

Tecnon Smart Display Technology Shenzhen Co., Ltd.